PROJECT LENGTH: 15 Weeks

PROJECT GOAL: Design a power-operated handheld tool for a specific user and task that supports optimal user experience and connects meaningfully to an existing brand

PROJECT SKILLS: Ideation, Research, Sketching, CAD Modeling, and Model Making

IMMERSION EXPERIENCE

I began by reaching out to real people who use power tools every day at their jobs:

a prosthetist, a plumber, and a neon sign maker.

Tom, the second-generation neon sign maker, caught my attention.

TASK ANALYSIS

After speaking with Tom and gaining an understanding of his workflow, I needed to analyze his process. Hiccups in Tom's process are opportunities for my design!

RESEARCH

The tools currently used for glass tube bending in neon sign making are and low-tech. Most existing torches vary in size and cost but are uniformly rigid, limiting their ability to adapt to different glass types and bending techniques. These constraints reveal a gap in the market for innovation in torch design.

DESIGN GOAL

This project aims to modernize traditional torch technology by developing an adjustable, flexible design that supports a wide range of glass-bending techniques. By enhancing flame control and precision, the torch will better accommodate various glass types and workflows—offering a more efficient, responsive, and adaptable tool for today’s neon fabricators.

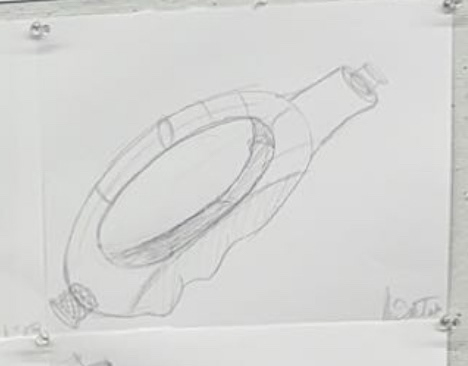

SKETCHING IDEATION

With my research, my design goals, and my mood board, I could begin sketching ideas for the overall form of the torch. From there, with input from my peers and professors, I could choose my top 5 potential designs.

MODEL MAKING

Using my top 5 sketch ideas, I created orthographics of each and carved foam models by hand. I took them to my peers for feedback, and then made another set of models with a band saw and hand file, focusing on ergonomics.

INTERNAL MECHANISM

At this point, I needed to determine how exactly my torch would be adjustable. I knew the internal mechanism would be complex and could be a determining factor in the form, so I began to develop it.

After much trial and error and discussions with my professors, I determined that a parallelogram linkage system, the movement facilitated by a rack and fixed pinions, would be the ideal mechanism for this project.

BRANDING

Looking back at my mood board, I knew I wanted to go for an industrial aesthetic, so I looked at brands that coincided with that.

Zippo came to mind. Timeless design, reliable, and “engineered for life”. Everything I wanted my torch to be. I made a board of existing Zippo products to help influence my design.

CAD DEVELOPMENT

Once my mechanism was determined, I was able to model it in Fusion360.

Using major influence from Zippo’s existing design language and my modeled internal mechanism, I was able to model my torch's casing.

FINAL MODEL PREP

My final model was 3D printed. I filled in the grooves with plaster and sanded until the piece was smooth. Then I sprayed it with automotive filler primer and sanded between coats until it was extremely smooth. I also coated and sanded the bolts and rope (representing the mesh tubing).

FINAL POSTER & MODEL

Our final requirement for the project, in addition to the model, was to create a poster for your designed product, including research, design goals & objectives, orthographics, and final renderings.