PROJECT LENGTH: 5 Weeks

PROJECT GOAL: Gain and use knowledge of joinery and general woodworking to create a unique furniture piece.

PROJECT SKILLS: Ideation, CAD Modeling, and Woodworking

INITIAL IDEATION

This project was extremely vague in the sense that I was allowed to build quite literally anything. So, to begin my ideation, I went back to the basics, DESIGN = EMPATHY, and asked myself who or what I could be empathetic towards.

My newlywed sister happened to be my first and favorite thought. Being only 5'3", I know she has always struggled to reach the top shelves and cabinets. After watching her climb on her brand-new countertops in her new home, I knew she needed a solution.

INSPIRATION

I knew I wanted to make something personal for my sister. So, I visited the church where she was to be married and studied all the details.

The pews called to me immediately because of their banding and unique angled design. They were unlike any other I had seen.

CAD MODELING

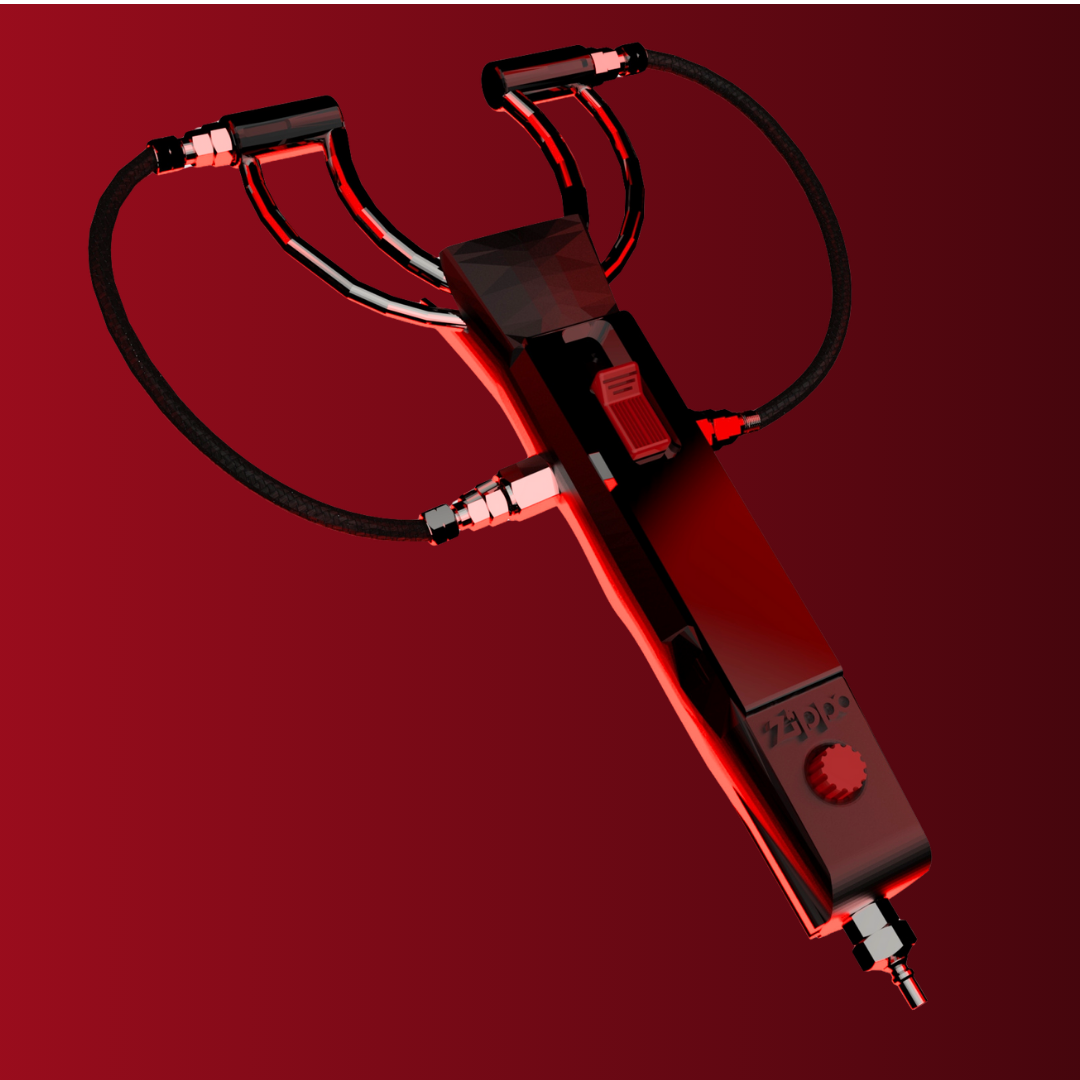

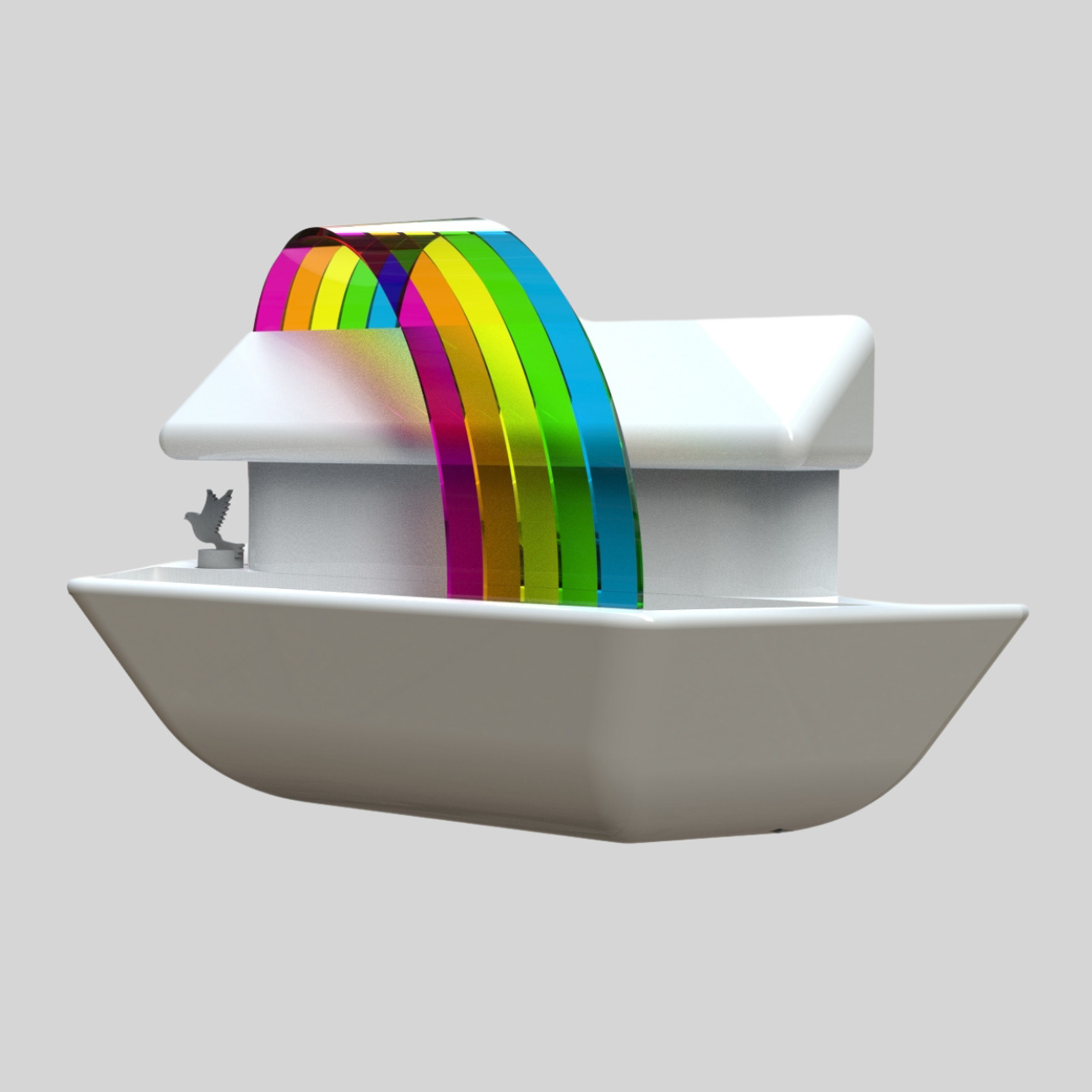

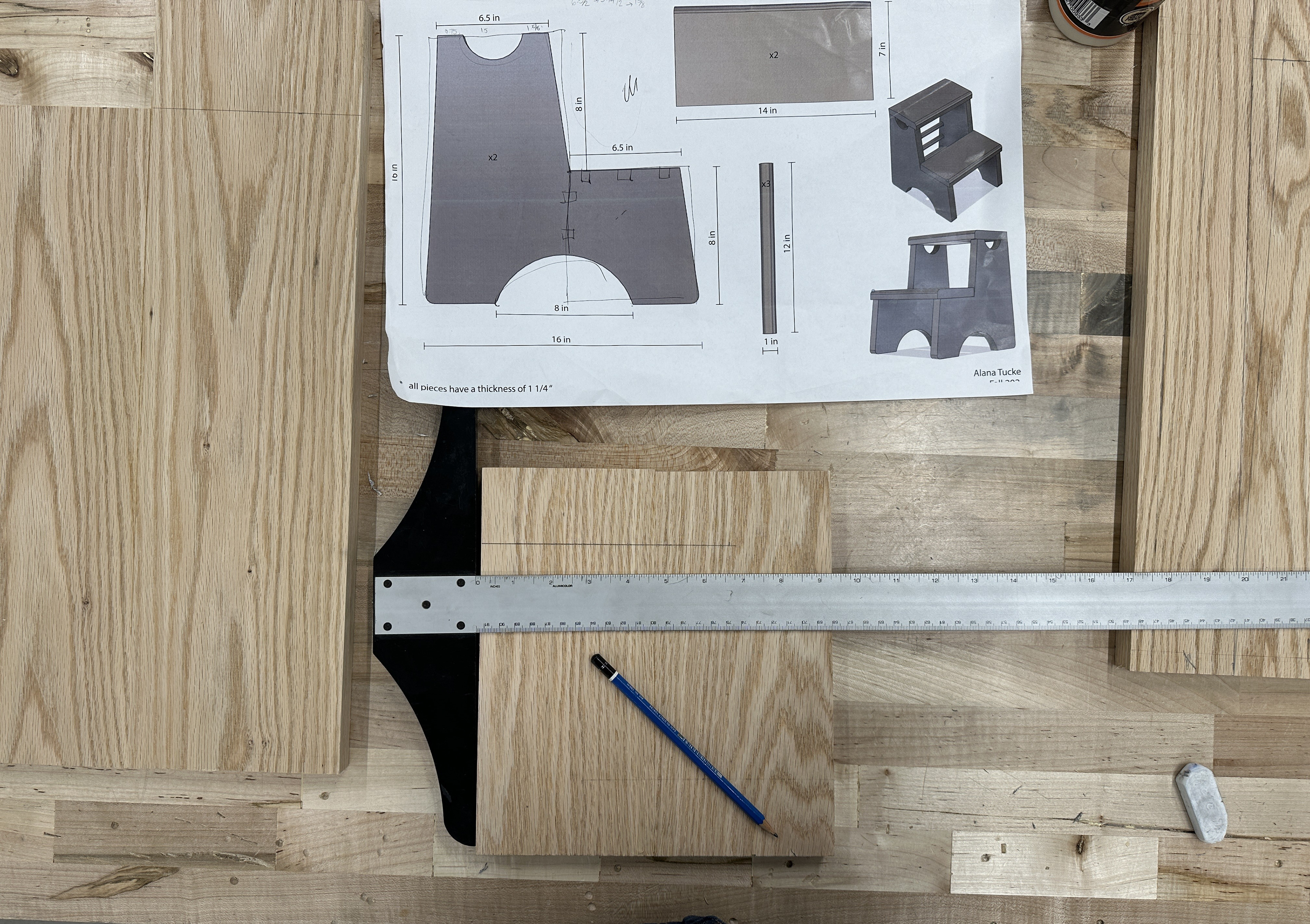

After sketching, I dove right into modeling in Fusion360. I made a simple orthographic to reference while in the woodshop, as well as a colored/textured render.

INTENTIONAL CHOICES

My material of choice was Red Oak. This variety of wood was an intentional choice as my grandfather had built my sister a bench out of it, so I wanted the pieces to match. I wanted to use recycled wood for this project, and I was able to find enough scrap pieces of the variety to fulfill my needs.

CHANGES

Using scrap wood, I made my first iteration model to practice my cuts and joinery techniques as well as refine any aesthetics. At this point, I only made one major change, going from three rungs to a singular one. The stability of the model stool was impressive, and my decision was solidified after testing and getting feedback.

IN THE SHOP

After joining, planing, and laminating my wood together, I got to work in the shop. I used several different machines, such as the chop saw and the band saw, to make my cuts. Then I used a domino tool for all of my joinery.

PROBLEMS ARISE

A negative side effect of using recycled and scrap wood is working with such a limited amount. A kickback from the chop saw split a piece of wood. I had to pivot and find a way to fit all the pieces I needed for my stool onto the undamaged wood.

A mistake with a setting on the domino tool put holes directly through the stool's tread. The only way to fix this without buying new wood, or sacrificing the quality of my work was to shrink the width of the stool from 14" down to 11".

ASSEMBLY AND FINISHING

Once all my cuts were finished, I could finally assemble my stool. I did this simply by coating my domino holes and the dominoes themselves in wood glue and using a mallet to push them in.

I finished the stool by staining it with 2 layers of Golden Oak. Once that was dry, I carefully sealed the wood with 3 coats of polyurethane.

FINAL PHOTOGRAPHS